- Home

- About Us

Our Customers

Certificates and Honors

Our company, by receiving golden certificates and winning the title of Rubber Products Manufacturer in the 2022 Top Brand Marathon, as well as adhering to international standards, has always taken steps to enhance the quality and safety of its products. Our achievements in the rubber industry reflect our commitment to innovation and excellence

Won the Golden Badge and the Rubber Products Manufacturer Brand in the 2022 Top Brand Marathon.

Won the Golden Badge and the Rubber Products Manufacturer Brand in the 2022 Top Brand Marathon.

Won the Golden Badge and the Rubber Products Manufacturer Brand in the 2022 Top Brand Marathon.

Key Strategies for Customer Satisfaction and Sustainable Development

Our Goals

Our goal is to attract targeted, efficient, and trained personnel to improve the production process and ensure customer satisfaction.

Our Vision

Our vision is to expand global markets through effective marketing and the use of modern technologies available internationally.

Our Mission

Our mission is to achieve customer satisfaction by meeting their qualitative and quantitative demands and providing accurate, comprehensive, and timely products and services.

Achievements and Honors of Kashan Rubber Industries: Innovation, Superior Quality, and Presence in International Markets.

The only rubber products manufacturing unit in the country with certification from SAKEMI Italy

Registration of two patents for the production of rubber liners for ball mills in ceramics, sanitary porcelain, and mining industries

Design and Patent of Spiral Hose, holder of the European CE mark

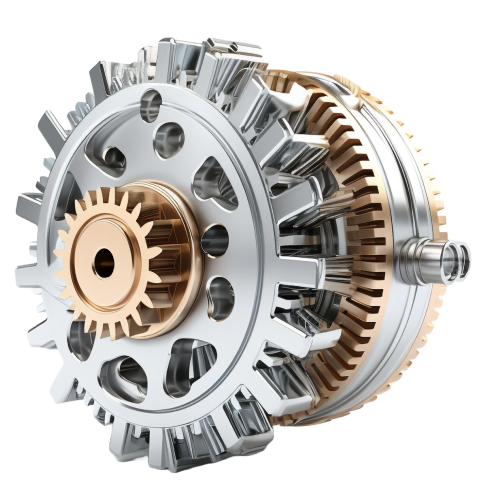

Introduction to the Units of Kashan Rubber Industries

Production unit

This unit is another proud achievement of the company, which, relying on modern machinery and specialized personnel, has taken a significant and steady step in the production of these products. Depending on the type and customer requests, it produces high-quality and globally competitive products

Laboratory unit

Technical and Engineering Unit

1 – Technical and Formula Design Unit: The specialists of this unit are responsible for designing formulas according to customer requests and testing the company’s input materials.

2 – Drawing Unit: This unit designs molds for custom parts and maps products.

3 – Quality Control and Inspection Unit: This unit plays the most important role in producing quality products according to customer requests and is responsible for strict and precise supervision and inspection in all stages of producing parts and customer orders, from formula design; compound production; mold construction and production.

4 – Warranty and After-Sales Service Unit: Providing valid bank guarantees of two to three years and handling customer affairs.

5 – R&D Research and Development Unit: Investigating the production of new products in line with world knowledge in the field of machinery; production conditions, as well as designing exclusive products. To date, it has been able to register 3 designs as inventions in the country’s Document Registration Office.

6 – Production Planning Unit: Designing the production schedule for all product lines and announcing the most accurate production and delivery times to customers, as well as assessing the feasibility of orders.

7 – Experts and installers to: Provide appropriate advice to customers to choose the best product; dispatch installers for Rubber Lining Liner products; conveyor belts and hot and cold apparatus.

Research and Development Unit

Certificate Control Unit and Requirements Establishment

Pioneer in Innovation

The first and only manufacturer of ceramic paper in Iran

Superior Quality

Holder of the CE certification and presence in international markets

Services and Support

A team of specialists and technical experts with an outstanding track record

Our Competitive Advantages

Winning three trophies as a manufacturer and exemplary industrial unit of Isfahan province.

Receiving the trophy for Exemplary Industrial Unit in the years 2013 and 2012.

Exporting to over 30 countries in the Persian Gulf and Central Asia

Quick Contact Form

For your convenience, you can enter your information in the box below, and our experts will contact you

Sales Unit :

09138296237

Our experts are with you!